Daily Inspiration: Just-in-time knowledge – “Your ability to get the right knowledge at the right time for the right purpose for the right situation. That’s power!”

August 1, 2023, BY JimCarroll"'Just-in-time knowledge' - Your ability to get the right knowledge at the right time for the right...

Daily Inspiration: Are You Fred, or George?

March 26, 2019, BY JimCarroll“Are you Fred or George? Wilma or Jane?” - #Futurist Jim CarrollYour answer probably...

Article: Artificial Intelligence & Robotics In Construction: ‘Massively Transformative’

January 17, 2019, BY JimCarrollWhen I spoke in Oman last November, I spent a little bit of my time on stage talking about...

Video: “Innovation: So What Do You Do Monday Morning?”

August 21, 2018, BY JimCarrollHere's a clip you'll need to get you thinking. I was brought in by a manufacturing company to...

Video: Tag & Label Institute Pre-Event Videos (Future of Manufacturing)

August 13, 2018, BY JimCarrollIn October, I will keynote the Tag & Label Institute annual general meeting in Amelia...

The Story Behind the Picture: Saving People From Themselves

April 12, 2018, BY JimCarrollIt was pretty ironic to be doing a talk a month ago on the future of manufacturing -...

Stage and topic highlights: 2nd Half of 2017 … Tokyo, Detroit, Dallas…. Disruption, Transformation and More!

November 20, 2017, BY JimCarrollWhat does a global futurist do? Assist clients in understanding the key trends which are impacting...

Yes, I speak the language of ‘global!’

November 3, 2017, BY JimCarrollA question came in from a potential client last night, and after writing a long answer, I...

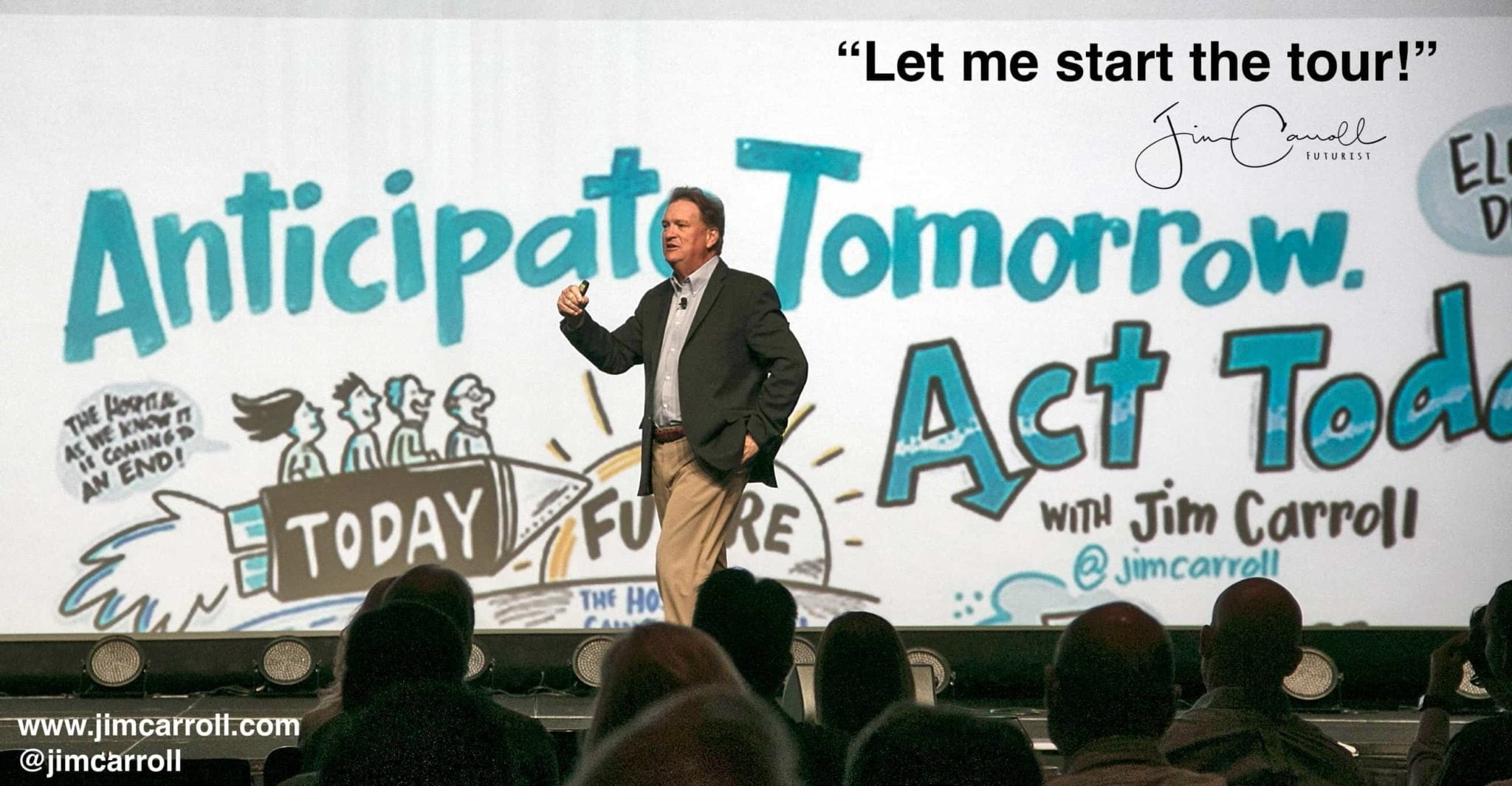

Trend Keynote: There’s More to Disruption Than You Think There Is!

October 27, 2017, BY JimCarrollDisruption is real, it's big, and it's happening faster than you think. My job as a futurist has...

GET IN TOUCH

Jim's Facebook page

You'll find Jim's latest videos on Youtube

Mastodon. What's on Jim's mind? Check his feed!

LinkedIn - reach out to Jim for a professional connection!

Flickr! Get inspired! A massive archive of all of Jim's daily inspirational quotes!

Instagram - the home for Jim's motivational mind!