Daily Inspiration: “Creativity capital, experiential capital, collaborative capital, generational capital – these are now the new requirements necessary for innovation success!”

February 8, 2024, BY JimCarroll"Creativity capital, experiential capital, collaborative capital, generational capital - these are...

Daily Inspiration: “Mastering the future? It’s more about awareness than it is about genius!”

August 30, 2022, BY JimCarroll"Mastering the future? It's more about awareness than it is about genius!" - Futurist Jim...

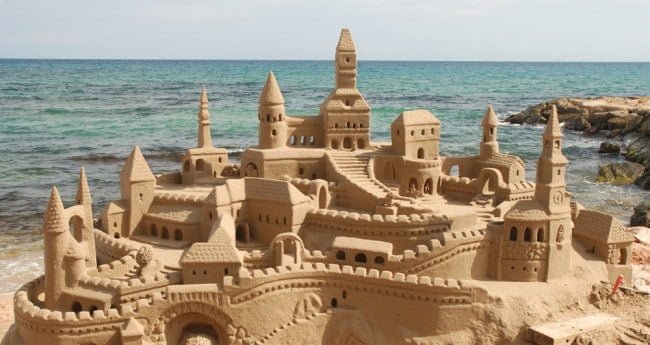

Why Innovation Thrives in the Building of Sandcastles!

February 16, 2019, BY JimCarrollI'll be busy studying some key innovation issues for the next week. I have assembled a crack...

19 Trends for 2019: #15 The Acceleration of Generational Transformational Change

January 22, 2019, BY JimCarroll"All your base are being to us!" That's what happens with the transfer of control of the...

19 Trends for 2019: #6 The Gaming Generation Virtualizes Work

January 9, 2019, BY JimCarroll#6 - The Gaming Generation Redefines the Future of WorkFarmville redefines farming. Fortnite...

Article: “FitBits for Cows: The Future of Agriculture is Hyperconnected!

January 8, 2018, BY JimCarrollThe folks at Farm and Dairy Magazine interviewed me on trends to watch in 2018 in the world of...

Yes, I speak the language of ‘global!’

November 3, 2017, BY JimCarrollA question came in from a potential client last night, and after writing a long answer, I...

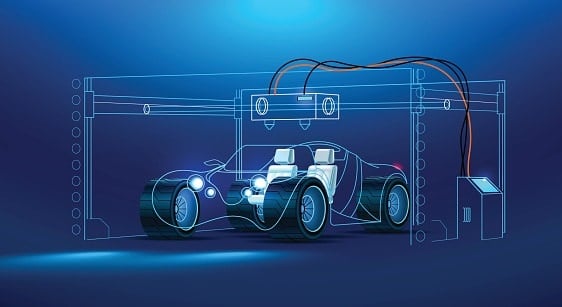

Article: The Fabricator – “A look into the future of manufacturing”

October 18, 2017, BY JimCarrollAnother article on a recent keynote I did on the future of manufacturing; in this case, from The...

Article: Futurist Says “Fast & Furious” Changes Coming to Manufacturing

October 6, 2017, BY JimCarrollThe folks at New Equipment Digest interviewed me a few weeks back for an article on...

GET IN TOUCH

Jim's Facebook page

You'll find Jim's latest videos on Youtube

Mastodon. What's on Jim's mind? Check his feed!

LinkedIn - reach out to Jim for a professional connection!

Flickr! Get inspired! A massive archive of all of Jim's daily inspirational quotes!

Instagram - the home for Jim's motivational mind!