Daily Inspiration: Personal Success – “Your best story is the one you have yet to share!”

March 8, 2024, BY JimCarroll"Your best story is the one you have yet to share!" - Futurist Jim CarrollIt’s book week!...

Daily Inspiration: Speed and Agility – “Be the cheetah, not the turtle”

February 14, 2024, BY JimCarroll"Be the cheetah, not the turtle" - Futurist Jim Carroll In Hawaii, you can swim...

Daily Inspiration: “Never lose sight of all the other opportunities while you are caught in the glare of the big shiny object!”

May 30, 2023, BY JimCarroll"Never lose sight of all the other opportunities while you are caught in the glare of the big shiny...

Short, Sharp Shocks of Strategic Insight: Why CEOs Are Accelerating their Offsite Leadership Meetings (Part 1 of 2)

March 27, 2023, BY JimCarrollSome years ago, I wrote an article for one of my representatives, the Washington Speakers Bureau....

Daily Inspiration: “If only the paranoid survive, it’s also true that it’s the chameleons who will thrive!”

January 27, 2023, BY JimCarroll"If only the paranoid survive, it's also true that it's the chameleons who will thrive!" - Futurist...

Daily Inspiration: “Mastering the future? It’s more about awareness than it is about genius!”

August 30, 2022, BY JimCarroll"Mastering the future? It's more about awareness than it is about genius!" - Futurist Jim...

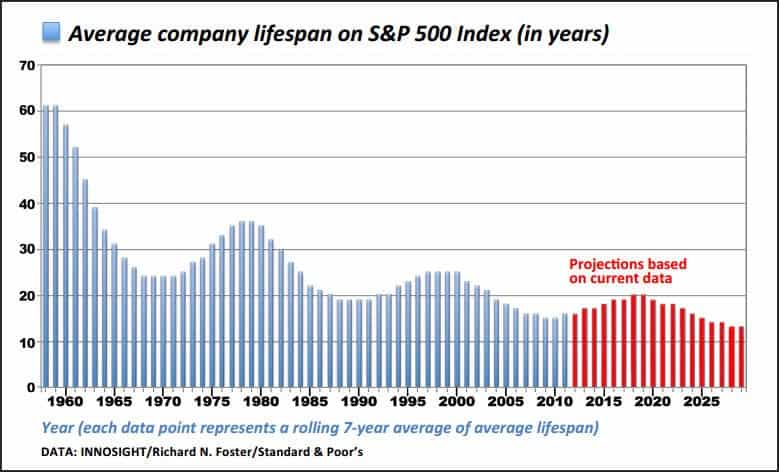

Innovate and Adapt – or Die: The Sobering Reality of Disruption

December 7, 2021, BY JimCarrollIt's that simple.Here's a simple list of companies that were once great successes. Then they...

Article: Artificial Intelligence & Robotics In Construction: ‘Massively Transformative’

January 17, 2019, BY JimCarrollWhen I spoke in Oman last November, I spent a little bit of my time on stage talking about...

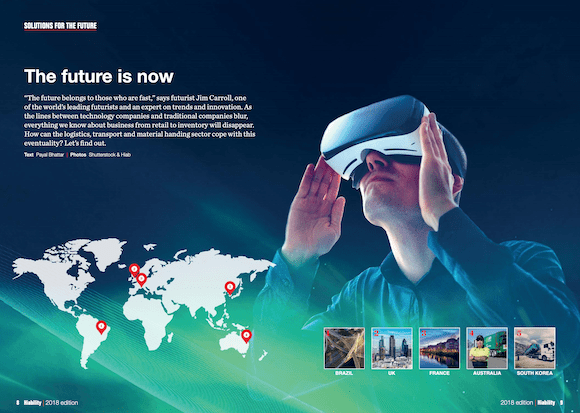

Article: The Future of Logistics & Supply Chain

October 11, 2018, BY JimCarrollThe folks at Hiability decided they needed to share with their customers and their industry the...

GET IN TOUCH

Jim's Facebook page

You'll find Jim's latest videos on Youtube

Mastodon. What's on Jim's mind? Check his feed!

LinkedIn - reach out to Jim for a professional connection!

Flickr! Get inspired! A massive archive of all of Jim's daily inspirational quotes!

Instagram - the home for Jim's motivational mind!