My dad was a chemical engineer. He worked hard working with science – first, at a basic chemicals company; then, managing process and engineering at a liquor manufacturing company, and finally being in charge of a major company that manufactured specialty chemicals. Finally, he worked for the environmental management group of a provincial government in Canada.

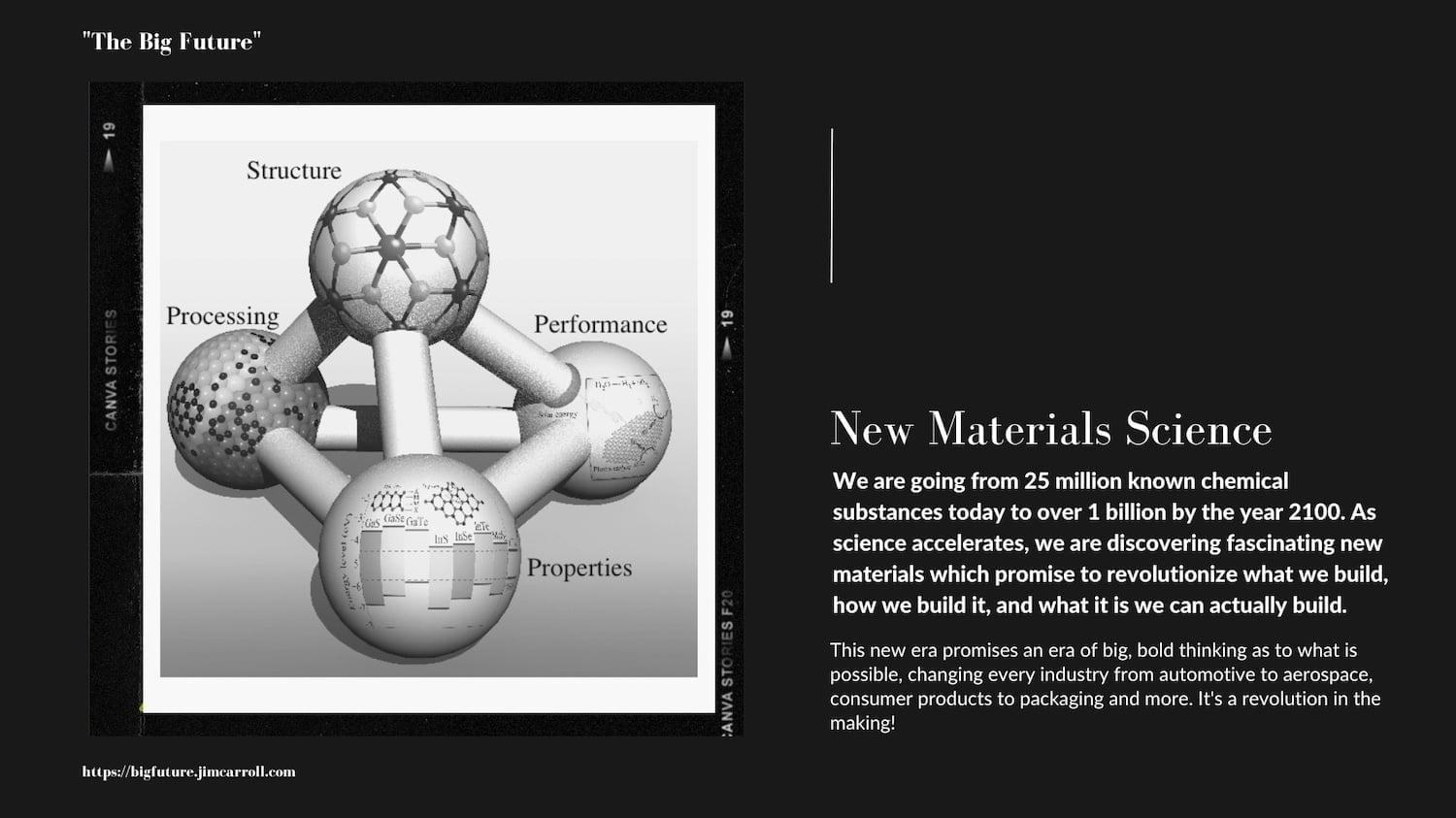

I will admit that I never really considered the work that he did to be tremendously exciting or important; as a young child, it wasn’t like a lawyer, a doctor, or a banker. Those were exciting professions! And yet today, I look at the world of chemical science to be one of the most exciting – and far-reaching – aspects of our future. That’s because we are going from 25 million known chemical substances today to over 1 billion by the year 2100. As science accelerates, we are discovering fascinating new materials which promise to revolutionize what we build,

how we build it, and what it is we can actually build. This new era promises an era of big, bold thinking as to what is possible, changing every industry from automotive to aerospace, consumer products to packaging, and more. It’s a revolution in the making!

We all use materials. We never really think about it too much though: the science behind their discovery, the acceleration of that science, and what it leads to in terms of new opportunities. That’s what this post is about – and it’s part of my BIG Future series.

Materials? Chemistry? As a futurist, my mind was opened up back in 2004 as I was preparing for a talk for an environmental government ministry. Somewhere during my research, I came across two fascinating observations as to how fast the world of chemical science was evolving.

First, I obtained from a chemical journal on the rapid evolution of knowledge/data in that field:

- to be up-to-date in all areas of chemistry you would currently have to read about 2,000 new publications every day

- if you prefer to screen only the short abstracts, you must read 200 pages per day or about 70,000 pages per year.

- furthermore, since the number of chemistry publications increases also exponentially, you need to double your reading capacity within the next 15 years.

- you must read 20 publications every day in order to grasp only 1% of the overall chemical publications!

I then found a research document that suggested that the result of this rate of advance is a rather exponential increase in the number of known chemical substances:

- “…The number of known chemical substances has been growing exponentially since 1800, from some hundreds then to about 19 million today….”

- “…. the number constantly doubles every 13 years….”

- by 2025: 80 million chemical substances

- by 2050: 300 million

- and by 2100: 5 billion……

19 billion known chemical substances to 5 billion? That’s a pretty exponential change…

Why? Consider this – it was the discovery of a single new chemical substance that led to the opportunity for Apple to miniaturize the hard drive — that led to the first iPod – many years ago. Which was the birth of a multi-billion market.

For every new chemical substance, similar massive new opportunities exist. That’s what it means to live in an exponential world! And that is what it means to focus on future opportunities through innovation.

A Tour of Materials Science

Most of us probably don’t spend much time thinking about ‘stuff.’ It’s all around us.

Materials science research is crucial in many areas, especially in the semiconductor space. The chips that power our electronic devices have got so miniscule that improving their performance and capabilities any further requires expensive specialised equipment and experts with PhDs in materials science to run those machines and conduct experiments.It’s a fascinating process of trial and error, of testing hypotheses and confirming theories,

Indian materials science work is now core to chips worldwide

24 November 2022, The Times of India

But why is it important? Virtually every single industry, new product discovery, and the invention is the result of materials science. Our faster discovery of new materials and new science leads us to:

- high performing batteries for next-generation energy storage

- lightweight materials for more efficient and energy-saving transportation

- new electrical and optical material for the continued acceleration of digital technologies

- improving the ability to meet our sustainability goals around energy, climate, and the environment

- the acceleration of biomaterial science, particularly related to the big trend of regenerative medicine explained earlier in this series

- the development of thin solar cells that generate more energy at a lower cost

- healthcare applications such as smart wound dressing not only protect the skin but help to heal it with controlled drug release

- technology that combines the advantages of glass and plastic without the potential disadvantages they may present for use in medical devices such as syringes, vials, blood collection devices, and tubes

The list goes on. Essentially, this aspect of science affects virtually every industry – power and telecommunications, aerospace, construction, biomedical, energy, healthcare, automotive, and sustainable development. Even the acceleration of brain science – in that new materials might help lower the risk of infection for new probes that might be used in brain surgery and the acceleration of computer-to-brain technology (discussed in one of my other BIG Future trends – The Acceleration of Brain Science.)

“These bioactive polymer- based electrodes can enable the conformal contact with irregular tissue and result in low inflammation when compared to conventional rigid inorganic electrodes. In this review, we focus on the use of silk fibroin and cellulose biopolymers as well as certain synthetic polymers to offer the desired flexibility for constructing electrode substrates for a conformal neural interface.

Science – Materials Science; Studies from Donghua University Further Understanding of Materials Science (Bioactive Polymer-enabled Conformal

Neural Interface and Its Application Strategies)

8 February 2023 Biotech Week

The thing is – there are some amazing ideas, fascinating discoveries, and accelerating opportunities coming together. Consider the amazing science of solar cells – what if we could develop “dual-sided solar cells.” What’s that? This!

The idea is as straightforward as it is simple: If I can collect both direct sunlight as well as its reflection via the rear end of my solar cell, this should increase the yield of energy the cell produces. Potential applications are, for instance, building-integrated photovoltaics, agrivoltaics – the simultaneous use of areas of land for both photovoltaic power generation and agriculture – and vertically or high-tilt installed solar modules on high-altitude grounds. Enter the bifacial solar cell. According to the International Technology Roadmap of Photovoltaics, bifacial solar cells could capture a market share of 70% of the overall photovoltaics market by 2030.

Swiss Federal Laboratories for Materials Science and Technology (EMPA); New process boosts efficiency of bifacial CIGS thin film solar cell

23 December 2022, Energy Weekly News

How might this work? Imagine a solar cell on a piece of farmland – the top part is generating energy, and yet the sun goes straight through the cell to provide needed sunshine for the growth of crops. That’s a revolutionary idea and yet, might not be all that far away. The folks involved in this aspect of materials science speak of achieving maximum ‘energy conversion efficiency’ – that’s the ability of the solar cell to generate energy. With this new aspect of science, the highest values achieved so far have been 9.0% for the front side and 7.1% for the rear side, but they want to achieve a goal of 33%. They are already moving towards that!

The cell yielded values of 19.8% for front illumination and 10.9% for rear illumination that had been independently certified by the Fraunhofer Institute for Solar Energy Systems (ISE) in Freiburg/Germany – in the very same cell on a glass substrate. What’s more, the team also succeeded in fabricating, for the very first time, a bifacial CIGS solar cell on a flexible polymer substrate, which – due to their light weight and flexibility – widens the spectrum of potential applications. And finally, the researchers combined two photovoltaic technologies – CIGS and perovskite solar cells – to produce a bifacial “tandem” cell. According to Tiwari, bifacial CIGS technology has the potential to yield energy conversion efficiencies beyond 33%, thus opening up further opportunities for thin film solar cells in the future.

Swiss Federal Laboratories for Materials Science and Technology (EMPA); New process boosts efficiency of bifacial CIGS thin film solar cell

23 December 2022, Energy Weekly News

This is the type of stuff that gets me excited about the future!

Bottom line – materials science matters. And if it is moving faster, the stuff we use in our daily lives will happen faster; new products are discovered faster; potential big challenges are solved faster. What’s critical to understand is that we are now moving into a new era accelerated by the acceleration of science.

Everything we use is made of a material. The paper (or screen) on which you are reading this article, your clothes, and electrical devices, the building you are in, and even you, are made from different types of materials. We live in a ‘material world’.

Many of us take materials for granted, but each one has been developed and selected to provide the best performance and cost for the job they are used for. Since the Stone Age, humanity has developed materials through the different ages to where we are now in the Molecular Age.

Career in Materials Science and Engineering

15 October 2022, The Hindu Online

What’s Behind the Acceleration of the Science?

Many things.

One has to do with the fact that the use of new methodologies simply lets scientists work faster. The use of AI, robotics, autonomous labs, and quantum physics all help to speed up the quest to discover new materials.

Collaborative science moves science forward faster; the simple fact that scientists can share their research and discoveries means that things just speed up.

In addition, the arrival of sophisticated 3d printing technologies has had a massive impact on this aspect of science, as it helps to move science from the theoretical to the practical faster.

All in all, the trend that led to our exponential world led to exponential science.

Living Materials (“Biomaterials” or “Bio-inspired”)

One of the most fascinating, long-standing but fast-evolving aspects of material science has to do with the idea of ‘living materials.’ For a long time, scientists have adopted the idea that the discovery of many new materials can come from studying nature itself, and adopting what is seen there as opportunities for innovation with new materials.

From pangolin scales that can stand up to hard hits to colorful but sturdy peacock feathers, nature can do a lot with a few simple molecules.

In a new review paper, a team of international researchers have laid out how engineers are taking inspiration from the biological world-and designing new kinds of materials that are potentially tougher, more versatile and more sustainable than what humans can make on their own.

“Even today, nature makes things way simpler and way smarter than what we can do synthetically in the lab,” said Dhriti Nepal, first author and a research materials engineer at the Air Force Research Laboratory in Ohio.

University of Colorado at Boulder; Learning from pangolins and peacocks: Researchers explore next-gen structural materials

14 December 2022, Defense & Aerospace Week

Which leads to the idea of ‘bioinspired’ materials.

The researchers, who come from three countries, delve into the promise and challenges behind “bioinspired nanocomposites.” These materials mix together different kinds of proteins and other molecules at incredibly small scales to achieve properties that may not be possible with traditional metals or plastics. Researchers often design them using advanced computer simulations or models. Examples include thin films that resist wear and tear by incorporating proteins from silkworm cocoons; new kinds of laminates made from polymers and clay materials; carbon fibers produced using bioinspired principles; and panes of glass that don’t easily crack because they include nacre-the iridescent lining inside many mollusk shells.

University of Colorado at Boulder; Learning from pangolins and peacocks: Researchers explore next-gen structural materials

14 December 2022, Defense & Aerospace Week

For example, silk:

“Bioinspired based materials have elevated rapidly over the past few decades. Bio-inspired strategies entail extracting fundamental components and reassembling them into programmable biomaterials. This method may improve its processability and modifiability, allowing it to meet the biological application criteria. Silk is a desirable biosourced raw material due to its high mechanical properties, flexibility, bioactive component sequestration, controlled biodegradability, remarkable biocompatibility, and inexpensiveness. Silk regulates temporo-spatial, biochemical and biophysical reactions.”

Silk-Based Biomaterials for Designing Bioinspired Microarchitecture for Various Biomedical Applications)

15 February 2023, Biotech Week

What is being explored is how the strength properties of silk might be further exploited for various medical applications, particularly in the field of regenerative science.

Another goal? How to find harder materials for use in different applications. Enter the lowly ginkgo seed – being examined for the potential to reduce cracking of materials.

Natural structural materials typically feature complex hierarchical anisotropic architectures, resulting in excellent damage tolerance. Such highly anisotropic structures, however, also provide an easy path for crack propagation, often leading to catastrophic fracture as evidenced, for example, by wood splitting. Here, we describe the weakly anisotropic structure of Ginkgo biloba (ginkgo) seed shell, which has excellent crack resistance in different directions. Ginkgo seed shell is composed of tightly packed polygonal sclereids with cell walls in which the cellulose microfibrils are oriented in a helicoidal pattern.

Ginkgo seed shell provides a unique model for bioinspired design

6 December 2022, Proceedings of the National Academy of Sciences of the United States of America

And then there is the field of living biological materials science! Consider this:

How could living materials be used in a home? Consider the benefits to be gained from a chimney that heals after damage, a roof that breathes to control airflow, surfaces that don’t flake or fade, and a driveway that eats oil to clean up after spills.

Living Structural Materials Could Open New Horizons for Engineers and Architects

14 August 2016, ForeignAffairs.co.nz

Or take it one step further:

The structural materials that are currently used to construct homes, buildings, and infrastructure are expensive to produce and transport, wear out due to age and damage, and have limited ability to respond to changes in their immediate surroundings.

Living biological materials—bone, skin, bark, and coral, for example—have attributes that provide advantages over the non-living materials people build with, in that they can be grown where needed, self-repair when damaged, and respond to changes in their surroundings.

The inclusion of living materials in human-built environments could offer significant benefits; however, today scientists and engineers are unable to easily control the size and shape of living materials in ways that would make them useful for construction. DARPA is launching the Engineered Living Materials (ELM) program with a goal of creating a new class of materials that combines the structural properties of traditional building materials with attributes of living systems. Living materials represent a new opportunity to leverage engineered biology to solve existing problems associated with the construction and maintenance of built environments, and to create new capabilities to craft smart infrastructure that dynamically responds to its surroundings.

“The vision of the ELM program is to grow materials on demand where they are needed,” said ELM program manager Justin Gallivan. “Imagine that instead of shipping finished materials, we can ship precursors and rapidly grow them on site using local resources. And, since the materials will be alive, they will be able to respond to changes in their environment and heal themselves in response to damage.”

Living Structural Materials Could Open New Horizons for Engineers and Architects

14 August 2016, ForeignAffairs.co.nz

Take it even further.

Scientists are making progress with three-dimensional printing of living tissues and organs, using scaffolding materials that sustain the long-term viability of the living cells. These cells are derived from existing natural tissues, however, and are not engineered to perform synthetic functions. And current cell-printing methods are too expensive to produce building materials at necessary scales.

ELM looks to merge the best features of these existing technologies and build on them to create hybrid materials composed of non-living scaffolds that give structure to and support the long-term viability of engineered living

DARPA intends to develop platform technologies that are scalable and generalizable to facilitate a quick transition from laboratory to commercial applications.

The long-term objective of the ELM program is to develop an ability to engineer structural properties directly into the genomes of biological systems so that neither scaffolds nor external development cues are needed for an organism to realize the desired shape and properties. Achieving this goal will require significant breakthroughs in scientists’ understanding of developmental pathways and how those pathways direct the three-dimensional development of multicellular systems.

Living Structural Materials Could Open New Horizons for Engineers and Architects

14 August 2016, ForeignAffairs.co.nz

In other words, the stuff of science fiction, suggests that one day, we might grow the foundation and walls of a home onsite using biological materials.

Want a bit of fun? Do a search for “living materials” or “engineered living materials” and you’ll get big, bold ideas like this:

Massive environmental opportunities

Then there are the BIG environmental challenges that could be solved with discoveries within the world of materials science.

Consider cement – it’s one of the largest generators of dangerous carbon dioxide in the atmosphere – but there are research programs underway that try to reduce that problem through the use of other materials:

“Increase of carbon dioxide in the environment has been associated with the onset of global warming, the greenhouse effect. Portland cement manufacture is a very large contributor to the carbon dioxide emissions with approximately 0.9 ton of carbon dioxide emitted for every ton of cement made. Concrete is second only to water as the most consumed substance in the world (hundreds of millions of tons worldwide) and Portland cement, with its huge carbon footprint, is the principal ingredient in concrete.

“The chemical process of making Portland cement is the reaction of limestone (calcium carbonate) with clay (hydrated alumino-silicate) at high temperatures. This elevated chemical reaction, called calcination, releases carbon dioxide to the atmosphere at a very high rate, for example, about 60% of the emissions from a cement plant. The high temperatures used for calcination reactions require combustion of carbon based fuels and are responsible for about 40% of the emissions of the cement plant.

“The above mentioned factors associated with Portland cement manufacture cannot be replaced so there is little that can be done to reduce carbon dioxide emissions from a cement plant. Thus, there is great need for an alternative to Portland cement based concrete as a structural building material.University of Central Florida Research Foundation, Inc. Patent Issued for Structural Materials with Nearly Zero Carbon Emissions

22 July 2016, Energy Weekly News

The patent? It’s for a method of using fly ash – generated by coal-burning power plants – within concrete mixtures that won’t decrease the strength of the concrete.

Or how about silk from the larvae of water butterflies, which might help discover a substance that could replace plastic:

Stone Age, Bronze Age, Iron Age- materials are so important to humanity that eras have been named after them. The name of the current period has been proposed as the plastic era, but a whole host of biomaterials are already being developed alongside and as a replacement for plastic.

Plastic enables our current lifestyle. If you think about traditionally measured properties of materials, such as durability, raw material availability, price and suitability for industrial production, plastic is an excellent material, describes researcher Sesilja Aranko from Aalto University.

In theory, a large part of plastic can also be recycled, but at least today, only less than ten percent of it is recycled globally.

Nowadays, we believe that it is necessary to find alternatives to plastic. They should meet the traditional requirements for raw materials, but in addition they should be ecological throughout their life cycle and completely biodegradable.

Researchers in Finland and around the world are developing new methods to utilize raw materials and produce next-generation materials. They can also have self-healing properties.

The model can be taken, for example, from the silk fiber produced by the larvae of water butterflies. It can be stretched, and when the load is removed, the fiber bonds are able to form again.

Biomaterials replace plastic

12 February 2023, STT

This is where the phrase ‘bio-inspired’ comes from – how can use nature to inspire us to discover new discoveries?

Bold goals everywhere.

Then there is the whole issue of materials science that has to do with making materials lighter.

“For most products which are to be handled and/or carried by consumers, the consumer typically prefers lighter weight products while not wanting to lose any product quality or durability. Lighter weight products, in addition to being more desirable for consumers, are often also preferred by manufactures in order to reduce shipping and handling costs. Essentially everything from raw materials and parts to finished products need to be shipped from their point of origin to the consumer.

Empire Technology Development Llc; Patent Application Titled “Light Weight Structural Materials” Published Online

1 January 2016, Energy Weekly News

Not only might we achieve energy and cost savings – airplanes that are lighter, trucks that are less heavy thereby getting better mileage – but we might also reduce harmful emissions:

“Other issues may also arise from the selection of the types of materials used for product production. Electronic products are constantly being improved and upgraded, and environmental impacts can result from the large volumes of consumer electronic products that enter into and phase out of the market each year. Certain materials used to produce products for consumers and industries require manufacturing processes that are energy intensive and generate large amounts of greenhouse gas and environmental waste. In addition, many waste products end up in landfills, and the materials may persist in the environment for thousands of years.

“Therefore, there is an increased need for ultra-lightweight materials that are not energy intensive to produce, and which are easy to recycle and preferably biodegradable, but significant technological needs remain unmet. New lightweight and ultra-lightweight materials are needed that are durable (i.e. impact-, crack-, rupture-, fatigue-, and corrosion-resistant), formable, transparent, non-toxic, inexpensive to fabricate, manufactured using low environment impact processes, and biodegradable. For certain applications, improved thermal conductivity, electrical conductivity, and optical transparency may also be relevant. Materials having reduced density/weight would be useful for applications in space, aerospace, vehicles, industrial products, consumer products, and everyday life in the human world.”

In addition to obtaining background information on this patent application, VerticalNews editors also obtained the inventors’ summary information for this patent application: “Presently disclosed are ultra-strong lightweight materials which incorporate hollow microspheres that have been treated in a manner that allows the spheres to be covalently bound within the material. The hollow microspheres reduce the density/weight of the product, while the covalent bonding between the spheres and the material provide a three dimensional bonded network to increase the structural integrity of the material. As an example, in an embodiment, ceramic microspheres may be functionalized by covalently bonding epoxy polymerizable groups to the microspheres, and a light weight epoxy product may be made by mixing the functionalized microspheres with an epoxy resin, followed by hardening of the resin so that the microspheres are covalently bound within the resin, take up a volume portion of the resin and thereby reduce the density/weight of the resin.

Empire Technology Development Llc; Patent Application Titled “Light Weight Structural Materials” Published Online

1 January 2016, Energy Weekly News

Critical Minerals

There are also big geopolitical issues that come with materials science as well – particularly with critical minerals.

Critical minerals are elements or compounds that have been deemed by the United States government to pose a significant risk in terms of supply and impact on our country. The United States Geological Survey (USGS) has been tasked with maintaining the critical mineral list which was last published in 2022. n1 The critical mineral list is created through an analysis of three criteria: (1) the likelihood of a supply disruption, (2) the impact to the nation’s economy and defense if a supply disruption occurs, and (3) if there is a significant supply risk existing. Of the 87 elements that are used for manufacturing, 50 are on the list! This fact alone reveals the dire situation that our country faces in terms of raw material supply as we are dependent on foreign countries, some of which are adversaries.

House Natural Resources Subcommittee on Oversight and Investigations Hearing; “Dependence on Foreign Adversaries: America’s Critical Minerals Crisis.”; Testimony by Michael Moats, Professor and Department Chair of Materials Science and Engineering, Missouri University of Science and Technology, Rolla, MO

9 February 2023, Congressional Documents and Publications

Materials science has become a thing of national defense and support – and this too accelerates the science of the science! Consider some of the stark realities for the US:

The importance of critical minerals can be seen in the modern devices that are important to all Americans. Gallium in the form of gallium arsenide phosphide and gallium nitride are essential for integrated circuits (semiconductor chips), laser diodes, light emitting diodes (LED)s, and radio frequency (RF) cellular used in smartphones. Tellurium is used in cadmium telluride, which is a high-efficiency solar collector utilized on 50% of the grid scale solar arrays in the United States and is combined with bismuth to produce thermal imaging night vision optics for civilian and military use. Indium is principally used as indium tin oxide in most flat panel displays and is growing in use in 5th generation (5G) fiber optic communications. Each of these critical minerals is captured during the processing of base metals. They are not mined and produced for their value alone. Therefore, the country that dominates base metal production controls the market for these minor tonnage

Many countries invested in new or upgraded metal production facilities that met heightened environmental standards. This did not occur in the United States. Many U.S. smelters and refiners could not compete economically against these newer facilities due to pressures to upgrade their plants to meet tighter environmental standards and declining ore grades at local mines. The 1980s and 1990s witnessed the closure of primary and secondary smelters leading to consolidation within the industry, which resulted in few companies willing to invest in their operations to potentially meet domestic demand. By 1995, the U.S. was producing 33% less alumina and 33% less zinc as compared to 1970.

Due to a significant technology advancement pioneered in Arizona, copper production increased by 44% from 1970 to 1995 n3. That advancement was an outcome of research on separation processes developed for uranium production with funding from the Department of Energy.

While the United States seemed content to outsource its metal production, China executed a different plan.

Over the past 27 years, the United States lost 30% of its copper mining capacity and 57% of its copper metal production). Meanwhile, China built 40 copper smelters and is presently planning to build four more to meet its internal demand. n5 This resulted in Chinese copper production increasing by 1570%! While Chinese copper mining has increased, most of China’s copper is mined elsewhere (e.g., Chile and Peru) and shipped as mineral concentrate. The Chinese mineral demand to feed its smelters and refineries occurs in several metal supply chains resulting in a “Mine for China” phenomenon that has swept through developing countries with mineral resources. China now produces 42% of the world’s refined copper, while the United States produces only 4%.

In 1995, the United States and China mined and smelted similar tonnages of zinc. During the past 27 years, China has increased its zinc production by 580% and now produces 45% of the world’s zinc. Meanwhile, U.S. production has declined 63% and only accounts for 2% of the world’s zinc. Zinc was added to the 2022 Critical Mineral list by the USGS.

Lead mining and metal production declined in the United States by 28% and 21% from 1995 to 2022. Domestic lead metal production has shifted completely to recycling with the last primary smelter in Herculaneum, Missouri, closing in 2013. Lead mining, smelting and battery production provides a $2.3 billion impact on the Missouri economy n6 and is still critical for all automobiles including EVs Again, while the U.S. lead production declined, Chinese production expanded dramatically. China now produces 44% of the world’s lead.

House Natural Resources Subcommittee on Oversight and Investigations Hearing; “Dependence on Foreign Adversaries: America’s Critical Minerals Crisis.”; Testimony by Michael Moats, Professor and Department Chair of Materials Science and Engineering, Missouri University of Science and Technology, Rolla, MO

9 February 2023, Congressional Documents and Publications

Suffice it to say – accelerating materials science has become a critical national defence and economic goals.

Carbon Nanotubes!

One of the most fascinating areas of research has to do with ‘carbon nanotubes!’

Nanotubes. Why are they important? Because they have two properties that are hard for most materials to achieve:

Most of the existing energy storage and structural materials have only one property between high strength or high energy storage capacity. By using carbon nanotube fiber that is light, strong, and has excellent electrical conductivity, the material developed by the two research teams has both properties simultaneously.

National Research Council of Science & Technology; High-strength and high energy storage capacity!

16 February 2022, Defense & Aerospace Week

What might discoveries in this field lead to? How about batteries that are actually a part of the structure itself? Consider drones:

Existing lithium secondary batteries, energy storage devices, do not withstand mechanical loads by themselves. On the other hand, structural materials including steel and aluminum are strong but, of course, they cannot store energy.

If a material can have both energy storage capacity and structurally excellent property, it can become an outer cover for vehicles and drones, and replace the existing battery, which reduces the weight and increase the driving distance.

To this end, a new material that is light and has excellent mechanical strength and good electrical conductivity is required to make a battery. The only material for this purpose is carbon nanotube fibers.

By researching on improving the productivity of carbon nanotube fibers, the technology can be improved for mass production within a few years. In addition, the localization and self-reliance of the new material can contribute to becoming a material powerhouse.

National Research Council of Science & Technology; High-strength and high energy storage capacity!

16 February 2022, Defense & Aerospace Week

In other words, the body of the drone IS the battery.

Lighter than Air Airplanes!

Think big and bold. What might this lead to? Back in 2019, I took on that topic with my ’19 Trends for 2019′ series. Follow the trend involving the exponentiation of pure science, and we might soon be able to architect aircraft that are lighter than air – just like that of Wonder Woman’s jet! That’s where the fast-emerging trend of new materials science might potentially lead us.

I’ve been covering this trend extensively within the many manufacturing conferences that I’ve been doing throughout the last year. When the trend is combined with the innovation offered by 3d printing, magic happens! Get a sense of what is going on with this short clip.

A few months ago, I found myself at Heathrow Airport, and while needing to kill some time before a flight, found a perfect opportunity to speak about the impact of this trend within the world of aerospace.

It’s for all these reasons anre more that faster materials science is one of my BIG trends for our BIG Future! Remember – we are going from approximately 25 million known chemical substances today to over 1 billion by 2100. With that acceleration of science comes … the acceleration of the future.

GET IN TOUCH

Jim's Facebook page

You'll find Jim's latest videos on Youtube

Mastodon. What's on Jim's mind? Check his feed!

LinkedIn - reach out to Jim for a professional connection!

Flickr! Get inspired! A massive archive of all of Jim's daily inspirational quotes!

Instagram - the home for Jim's motivational mind!